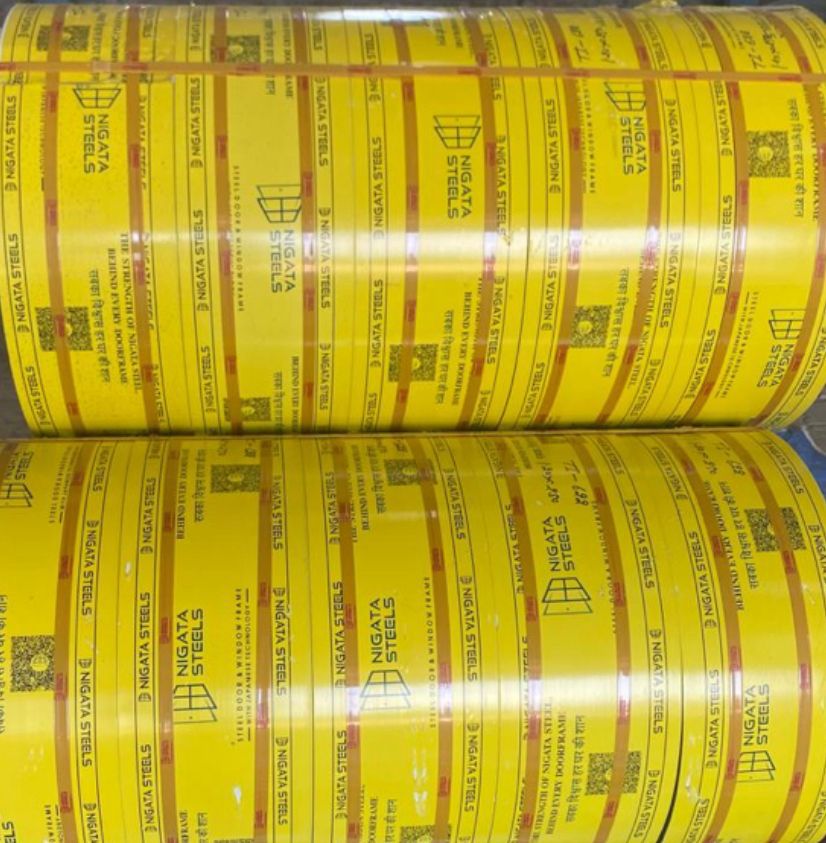

PPGI Slit Coils

Nigata Steels PPGI Slit Coils are made from high-grade zinc-coated steel, cut precisely to customer-specific sizes. Our PPGI slit coils provide excellent corrosion resistance, durability, and processing ease, making them perfect for high-performance manufacturing and construction applications. Prepainted with the color of your choice, they are ready for direct use in roll forming, CNC operations, and a variety of structural or decorative components due to their uniform coating and smooth finish.

Benefits Of Nigata PPGI Slit Coils

- Pre-painted & ready to use

- Corrosion resistant and long-lasting in all weather

- Lightweight and strong for easy handling and solid performance

- Smooth finish, ideal for visible parts like doors, panels, or facades

- Easy to form without cracking

- Less waste with slit-to-size production

- Faster manufacturing for improved roll forming speed

Advanced Multi-Layer Protection System

Base Metal (Galvanized Steel)

The coil’s core is made of galvanized steel, or steel that has been coated in a layer of zinc to stop corrosion.

Chemical Treatment Layer

This layer is applied to galvanized steel for improved corrosion resistance and the adhesion of the following coatings.

Primer Coating

The layer of chemical treatment is covered with a primer coating. It adds another layer of protection against corrosion and improves adhesion even more.

Paint Coating

Guard Film

Technical Specification

- Thickness Range : 0.40 mm - 2.00 mm

- Width Range: 50 mm - 1500 mm

- Zinc Coating : 220 GSM

- Base Substrate : Zinc coated steel

- Primer : Top - 5 microns, Back side- 5 microns

- Top Coatr : 20 microns - 25 microns

- Back Coat : 5 microns - 15 microns

- Colors: Top Coat - All Colors as per customer's requirement

Applications

- Window & Door Frames (Chaukhat)

- Roofing Sheet

- Wall Claddings

- Crimping Profiles

- Warehouses

- Cold Storage

- Decorative Containers

- Trunks

- Cooler Manufacturing

- Furniture

- False Ceilings

- Rolling Shutters

- Vehicle Bodies